Energy-Saving Fan Solutions: How Dajing Helps Industries Reduce Power Consumption

💡 Introduction

In today’s energy-conscious world, reducing power usage without compromising performance is vital. Industrial fans play a major role in factory energy efficiency.

1. The Impact of Fan Efficiency

A fan’s efficiency directly affects your system’s energy cost. Even a 5% increase in fan efficiency can save thousands in electricity each year.

2. Dajing’s High-Efficiency Design

Our fans feature:

Optimized impeller curvature for higher air output

Streamlined casing design to reduce air resistance

Precision dynamic balance testing for smoother performance

3. Intelligent Control System

The “Smart Fan Energy-Saving Package” developed by Dajing automatically adjusts fan speed according to system load, maximizing efficiency.

4. Proven Industrial Results

Clients in steel, cement, and chemical plants have achieved 15–30% energy savings after upgrading to Dajing’s high-efficiency fans.

5. Commitment to Sustainable Development

At Dajing, we combine innovation and responsibility to help industries achieve green, low-carbon growth.

Customer Testimonials

Trusted by industrial partners across 30+ countries — real feedback from our global clients.

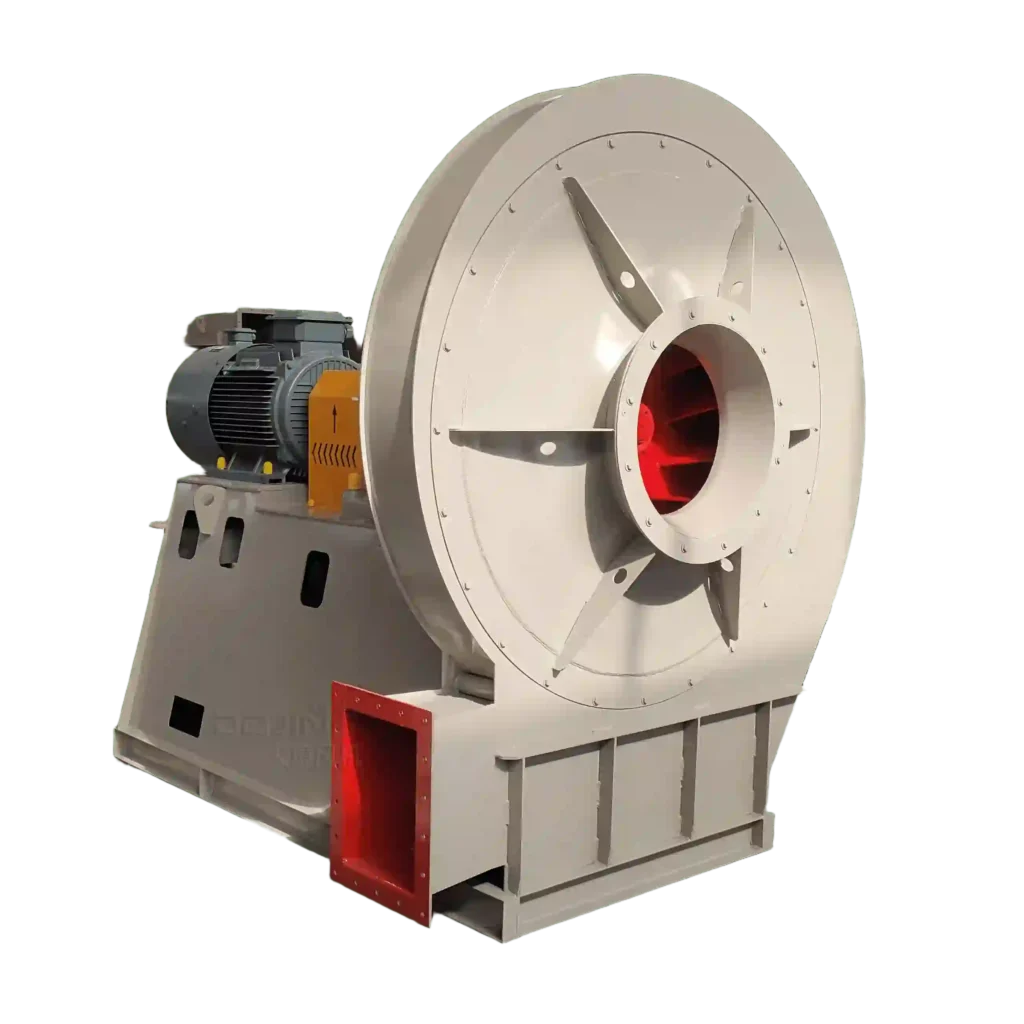

“We’ve been using Dajing’s 9-19 high-pressure centrifugal fans for our dust removal system. The airflow performance is excellent, and the noise level is much lower than our previous models. Truly reliable quality.”

FAQ's

Didn’t find the answer you were looking for?

Contact our engineering team for a customized solution.

Our engineers will recommend the suitable fan type based on your air volume, pressure, temperature, and working conditions.

You can also send your technical parameters or drawings directly for evaluation.

All Dajing fans are ISO9001 and ISO14001 certified.

Depending on customer needs, we can also provide CE, EAC, or other international compliance certificates.

Yes. We offer fully customized fan systems to meet special environmental or industrial requirements, including high-temperature, dust-removal, and corrosion-resistant designs.

Generally 15–30 working days after receiving the deposit, depending on the order quantity and customization level.

Yes. We provide online technical guidance, spare parts supply, and on-site service if required.

Our goal is to ensure your fan operates efficiently throughout its service life.