How to Choose the Right Industrial Centrifugal Fan for Your Application

💡 Introduction

Choosing the right centrifugal fan can significantly improve your system’s efficiency, stability, and energy savings. Whether you’re dealing with ventilation, fume extraction, or material conveying, proper fan selection is crucial.

1. Determine Your Airflow and Pressure Requirements

Start by defining air volume (m³/h) and pressure (Pa). These two factors dictate the fan’s impeller size and motor power.

2. Select the Right Type

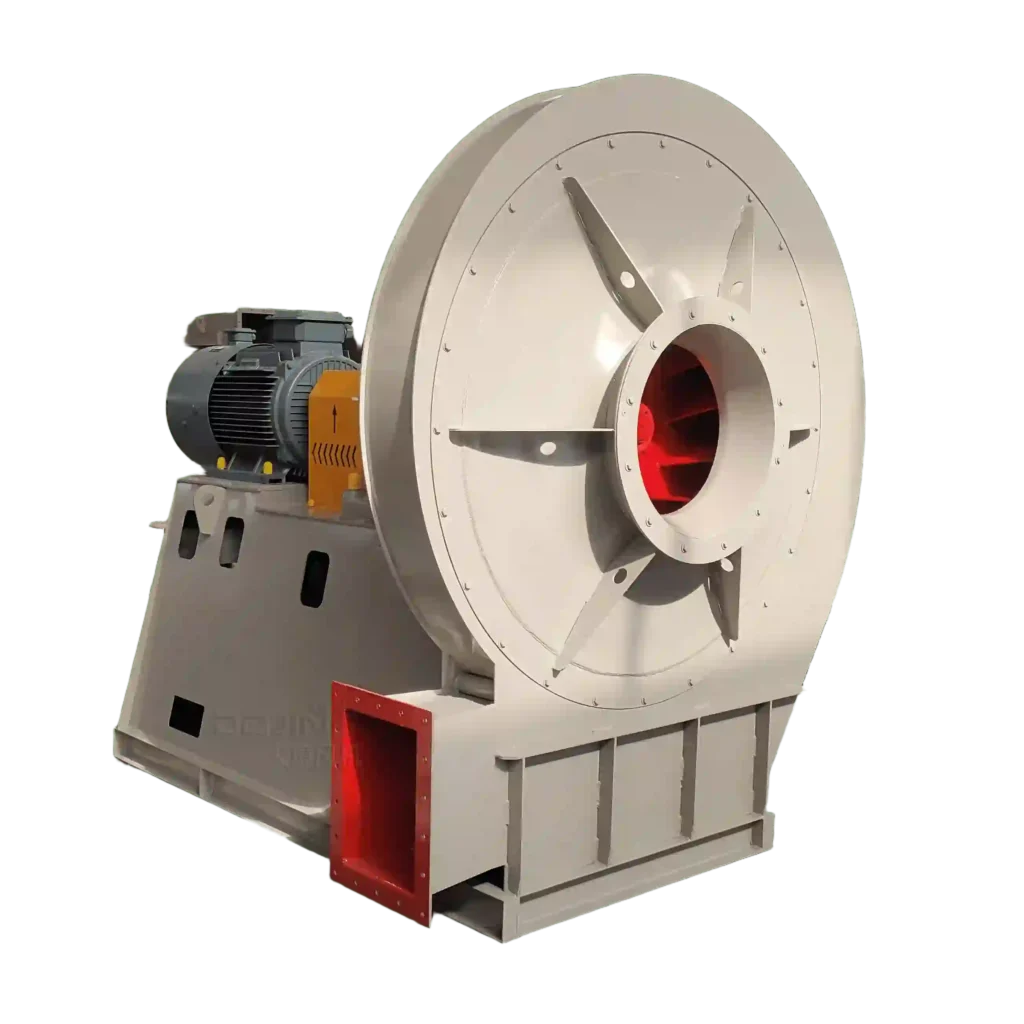

Dajing offers a full range of industrial centrifugal fans, including 4-68, 4-72, 9-19, and GY4-73 series, designed for different pressure and flow scenarios.

3. Consider Efficiency and Noise

Look for models with aerodynamic impeller design and low-noise operation. Dajing fans use precision-balanced rotors to ensure stable performance.

Check Material and Coating

For corrosive or high-temperature environments, stainless steel or anti-corrosion coatings can extend service life.

5. Ask for Professional Support

Our engineers provide one-on-one selection support to help you find the perfect match for your working conditions.

Customer Testimonials

Trusted by industrial partners across 30+ countries — real feedback from our global clients.

“We’ve been using Dajing’s 9-19 high-pressure centrifugal fans for our dust removal system. The airflow performance is excellent, and the noise level is much lower than our previous models. Truly reliable quality.”

FAQ's

Didn’t find the answer you were looking for?

Contact our engineering team for a customized solution.

We provide a complete range of industrial centrifugal fans, including 4-68, 4-72, 9-19, and GY4-73 series, suitable for ventilation, dust removal, material conveying, and boiler applications.

Customized designs and high-temperature or anti-corrosion models are also available.

Our engineering team offers one-on-one technical support.

Just tell us your working conditions — air volume, pressure, and medium type — and we’ll recommend the most efficient model.

We also provide CAD drawings and CAPP-assisted fan design for complex systems.

Prices depend on fan size, material, and motor power.

We offer EXW, FOB, CIF, and DDP terms.

Lead time usually ranges from 15 to 25 working days, depending on order quantity and customization level.

Yes. Dajing Fan exports to over 30 countries, and we cooperate with reliable freight forwarders to ensure safe and fast delivery.

On-site installation guidance and remote video commissioning are also available upon request.

We offer “Private Butler” Service, including:

1-hour quick response after receiving customer inquiries

2-hour technical feedback

24-hour full resolution commitment

Our service team can assist with troubleshooting, maintenance, and performance optimization.